Round Hole - The Most Popular Perforated Sheet Patten

According to the latest surveys, most perforated sheets are produced with round holes. Why? Round roles are manufactured relatively easier with aesthetic effects. The punching mold can last longer and can be easily manufactured and maintained which makes the round hole perforated sheet cheaper than any other perforated sheet with other hole patterns. Therefore, round hole pattern becomes the most popular shape.

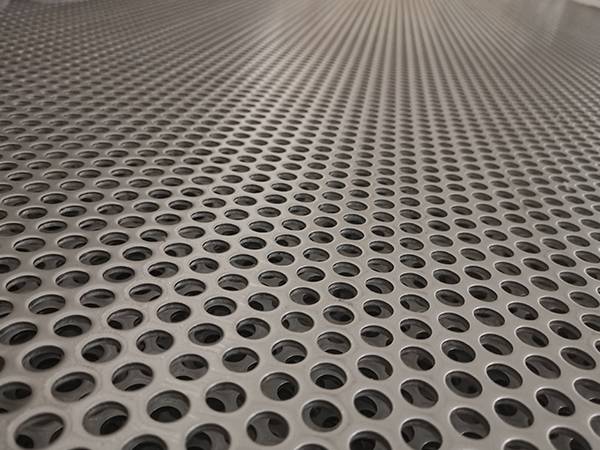

Aluminum round hole perforated sheet

Stainless steel round hole perforated sheet

Application

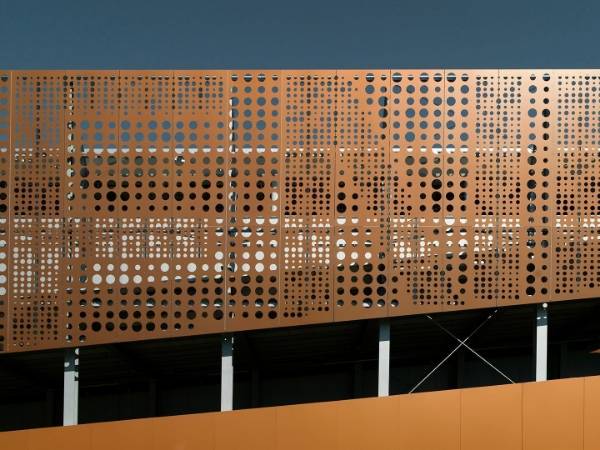

Today, the perforated sheet has been applied by designers in various fields, from industrial filters, noise barriers to building interior decoration, and facade cladding, perforated fences, etc.

Applications for round perforated sheets include:

Cladding and ceiling panels.

Sunshade and sunscreen.

Filter sheets for grain sieving, sandstone, kitchen garbage.

Decorative banister.

Protective fences of overpasses and machine equipment.

Balcony and balustrade panels.

Ventilation sheets, such as air condition grilles.

While obtaining semi-private effects and security, the space still maintains comfortable breathability, and airflow, forming a wonderful light and shadow effect. Perforated fences and banisters keep people safe and enclosed machines and other properties away from damage.

RHPS-3: Round hole perforated sheet with holes 5.00 mm diameter, pitch 6.5 mm, perforated plate thickness 1.0 mm. Materials can be available in steel, stainless steel, aluminum and copper.

Round hole perforated sheet we supply:

Material:

We specializes in manufacturing round hole perforated sheets in various high quality

materials including steel ( mild steel or carbon steel, no painting, galvanized or PVC

coated), stainless steel, aluminum, copper and brass or other materials as your request.

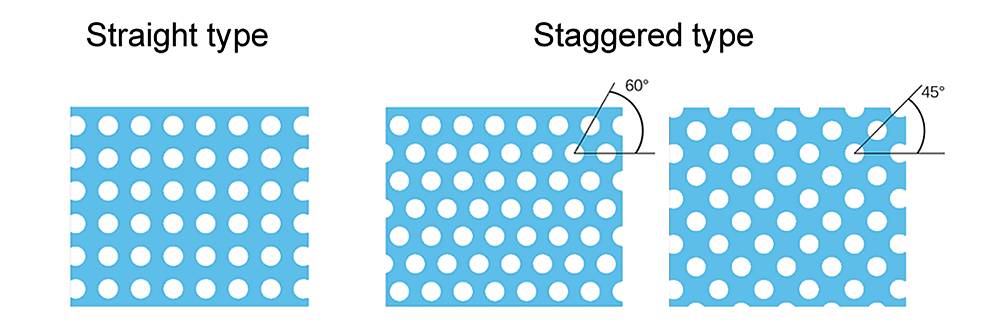

Hole pattern:

There are three ways of arrangements of round holes are adopted: straight type, 60°

staggered type and 45° staggered type as shown in the following picture:

Generally, the 60° staggered type is the strongest, most versatile one with high cost effectiveness.

Thickness:

Gauge 3 to 36 or as your requirements.

| Description | Hole Size (mm) | Pitch (mm) | Open Rate | Sheet Thickness | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.4 mm | 0.5 mm | 0.8 mm | 1 mm | 1.2 mm | 1.5 mm | 2 mm | 2.5 mm | 3 mm | 4 mm | 5 mm | 6 mm | ||||

| R0.8 T2 | 0.8 | 2 | 0.15 | * | * | * | |||||||||

| R1 T2 | 1 | 2 | 0.23 | * | * | * | * | ||||||||

| R1.2 T2.25 | 1.2 | 2.25 | 0.26 | * | * | * | |||||||||

| R1.2 T2.5 | 1.2 | 2.5 | 0.21 | * | * | * | * | ||||||||

| R1.5 T2.75 | 1.5 | 2.75 | 0.27 | * | * | * | * | ||||||||

| R1.5 T3 | 1.5 | 3 | 0.23 | * | * | * | * | ||||||||

| R1.8 T3.5 | 1.8 | 3.5 | 0.24 | * | * | * | * | * | |||||||

| R2 T3 | 2 | 3 | 0.4 | * | * | * | |||||||||

| R2 T3.5 | 2 | 3.5 | 0.3 | * | * | * | * | * | |||||||

| R2 T4 | 2 | 4 | 0.23 | * | * | * | * | * | * | ||||||

| R2.5 T3.5 | 2.5 | 3.5 | 0.46 | * | * | * | |||||||||

| R2.5 T4 | 2.5 | 4 | 0.35 | * | * | * | * | * | |||||||

| R2.5 T4.5 | 2.5 | 4.5 | 0.28 | * | * | * | * | * | * | ||||||

| R2.5 T5 | 2.5 | 5 | 0.23 | * | * | * | * | * | * | * | |||||

| R3 T5 | 3 | 5 | 0.33 | * | * | * | * | * | * | ||||||

| R3 T6 | 3 | 6 | 0.23 | * | * | * | * | * | * | * | * | ||||

| R3.5 T5 | 3.5 | 5 | 0.44 | * | * | * | * | * | |||||||

| R4 T5 | 4 | 5 | 0.58 | * | * | * | |||||||||

| R4 T6 | 4 | 6 | 0.4 | * | * | * | * | * | * | ||||||

| R4 T8 | 4 | 8 | 0.23 | * | * | * | * | * | * | * | * | ||||

| R5 T7 | 5 | 7 | 0.46 | * | * | * | * | * | * | ||||||

| R5 T8 | 5 | 8 | 0.35 | * | * | * | * | * | * | * | * | ||||

| R5 T10 | 5 | 10 | 0.23 | * | * | * | * | * | * | * | * | * | |||

| R5 T25 | 5 | 25 | 0.04 | * | * | * | * | * | * | * | * | * | |||

| R6 T8.5 | 6 | 8.5 | 0.45 | * | * | * | * | * | * | * | |||||

| R6 T9 | 6 | 9 | 0.4 | * | * | * | * | * | * | * | * | ||||

| R6 T10 | 6 | 10 | 0.33 | * | * | * | * | * | * | * | * | * | * | ||

| R7 T10 | 7 | 10 | 0.44 | * | * | * | * | * | * | ||||||

| R8 T11 | 8 | 11 | 0.48 | * | * | * | * | * | * | ||||||

| R8 T12 | 8 | 12 | 0.4 | * | * | * | * | * | * | * | * | ||||

| R8 T15 | 8 | 15 | 0.26 | * | * | * | * | * | * | * | * | * | |||

| R10 T13 | 10 | 13 | 0.54 | * | * | * | * | * | * | * | * | ||||

| R10 T14 | 10 | 14 | 0.46 | * | * | * | * | * | * | * | * | ||||

| R10 T15 | 10 | 15 | 0.4 | * | * | * | * | * | * | * | * | * | |||

| R10 T18 | 10 | 18 | 0.28 | * | * | * | * | * | * | * | * | * | |||

| R12 T16 | 12 | 16 | 0.51 | * | * | * | * | * | * | * | * | ||||

| R12 T17 | 12 | 17 | 0.45 | * | * | * | * | * | * | * | * | * | |||

| R15 T20 | 15 | 20 | 0.51 | * | * | * | * | * | * | * | * | * | |||

| R15 T21 | 15 | 21 | 0.46 | * | * | * | * | * | * | * | * | * | |||

| R20 T25 | 20 | 25 | 0.58 | * | * | * | * | * | * | * | * | * | |||

| R20 T27 | 20 | 27 | 0.5 | * | * | * | * | * | * | * | * | * | |||

| R20 T28 | 20 | 28 | 0.46 | * | * | * | * | * | * | * | * | * | |||

| R20 T30 | 20 | 30 | 0.4 | * | * | * | * | * | * | * | * | * | |||

| R25 T34 | 25 | 34 | 0.49 | * | * | * | * | * | * | * | * | * | |||

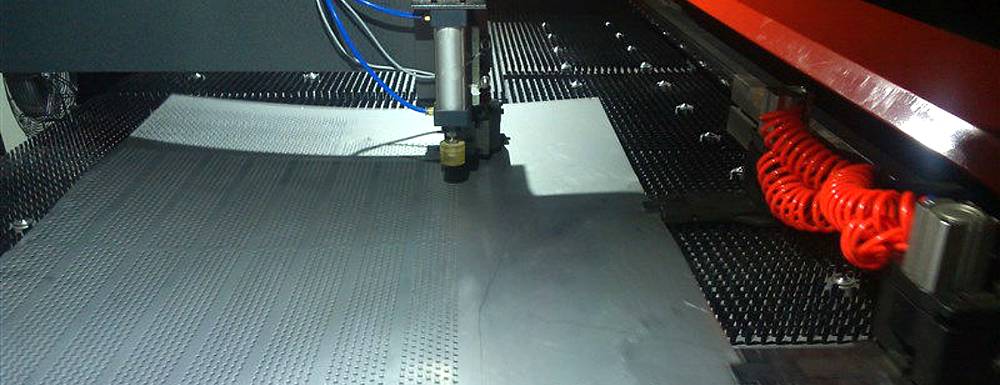

RHPS-4: Round hole perforated sheet is manufactured under strict quality control.

RHPS-5: Round hole brass perforated sheet for wall decoration

RHPS-6: Round hole perforated sheet for furniture manufacturing

RHPS-7: Round hole stainless steel perforated sheet for ceiling facade

RHPS-8: Round hole perforated sheet for stair handrail facade

RHPS-9: Round hole decorative panels for cladding

RHPS-10: Round hole decorative panels for sunshade

Inquiry for Our Product

Anping Zhuote Metal Products Co., Ltd.

E-mail:

info@perforatedsheet.ltd

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.