Aluminum Veneer Mesh for Walls, Interiors, & Suspended Ceilings

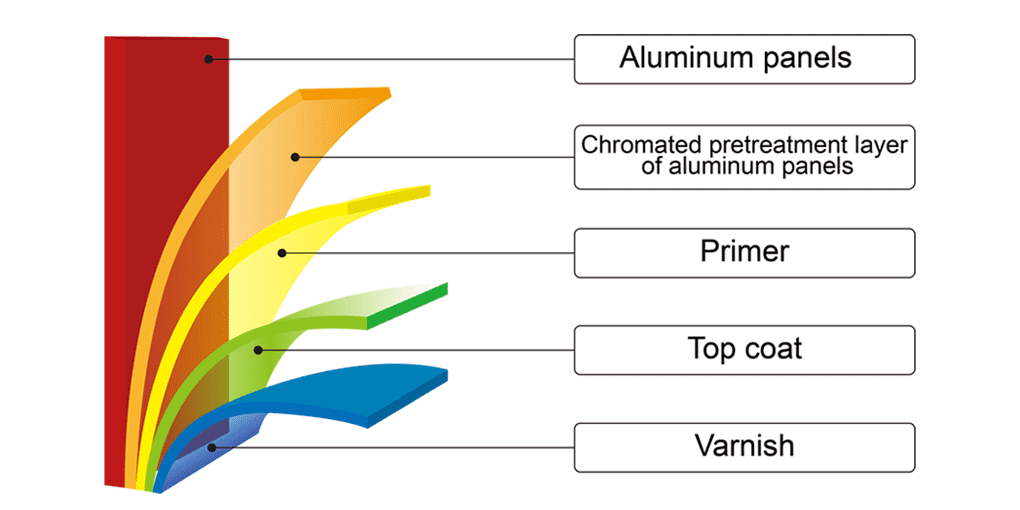

Aluminum panel/veneer is a new type of architectural decorative material, which adopts an aluminum alloy sheet as the base material, after chroming and other treatments, and then formed by CNC bending and other technologies. Its surface is treated with fluorocarbon coating, PVDF, or anodized technology, which makes it smooth, weather resistant, and easy to clean, so it is widely used in indoor and outdoor wall and roof materials of buildings.

Fluorocarbon coating is a kind of electrostatic coating technology, which has excellent resistance performance to fading, frosting, ultraviolet rays, cracks, and corrosion of atmospheric pollution (e.g. acid rain), and the ability to withstand harsh weather conditions, which are incomparable to general coatings.

Scope of application: walls, interiors, ceilings

Material Properties & Features

Compared with traditional building and renovation materials, aluminum veneer has the following advantages:

Light weight, good steel and high strength. 3.0 mm thick aluminum plate weighs 8 kg/m2, tensile strength 100–280 n/mm2;

Good durability and corrosion resistance. Using kynar-500, and hylur-500 as the base material of PVDF fluorocarbon coating, can resist acid rain, air pollution, and ultraviolet erosion, available for 25 years without fading;

Good craftsmanship. Using first processing and then the spray paint process, aluminum plate can be processed into plane, arc and spherical, and other complex geometric shapes, to meet the complex modeling requirements of the building;

Anti-coating uniformity and color variety. Advanced electrostatic coating technology makes paint and aluminum panels adhere uniformly and consistently between fluorocarbon coating colors of more than 100 kinds, the choice of space, is in line with the requirements of architectural aesthetics;

Not easy to be dirty, easy to clean and maintain. Because of the special molecular layout of kynar-500 in fluorocarbon coating, the dust on its appearance is not easy to adhere to, so it has a very strong cleanliness;

Installation and construction, convenient and quick. Aluminum panels are formed in the factory, no cutting is required at the construction site, and they can be fixed on the skeleton;

Recyclable and environmentally friendly. Aluminum plates can be 100% recycled, unlike glass, stone, ceramics, aluminum plastic composite panels, and other decorative materials, with high recycling residual value.

Processing & Types

Aluminum veneer curtain walls use high-quality high-strength aluminum alloy sheets. Its common thickness is 1.5 mm, 2.0 mm, 2.5 mm, and 3.0 mm. Aluminum veneer is used outdoors, its thickness should not be less than 2.0 mm, aluminum veneer is used indoors, and its thickness is agreed upon by the supply and demand sides.

Aluminum veneer used in the chemical composition of aluminum and aluminum alloy should be consistent with the requirements of GB/T 3190, and mechanical properties should be consistent with the requirements of GB/T 3880.2. Outdoor aluminum veneer should be 3XXX series or 5XXX series aluminum alloy. Aluminum veneer used outdoors should be coated with fluorocarbon with excellent weather resistance.

The conventional material of aluminum veneer has a maximum size of 1220 mm × 2440 mm and consists of panels, reinforcing ribs, and riveted angles. The surface is pre-treated with chroming and other pre-treatments and then treated with fluorocarbon coating, which is generally divided into two, three, or four coatings. Aluminum veneer after decades of development, has developed from the initial single type to a variety of types.

-

According to the shape of the aluminum veneer style, it can be divided into different types:

Conventional type

Imitation wood grain

Imitation stone

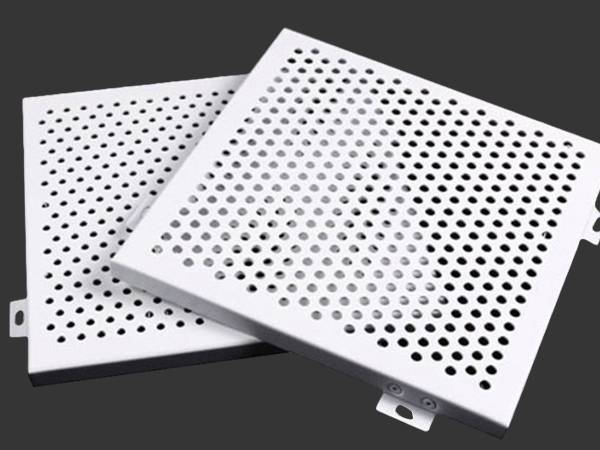

Perforated holes

Skeleton

Corrugated strip Conventional aluminum veneer: square aluminum veneer or rectangular aluminum veneer

Imitation wood grain aluminum veneer

Imitation stone aluminum veneer

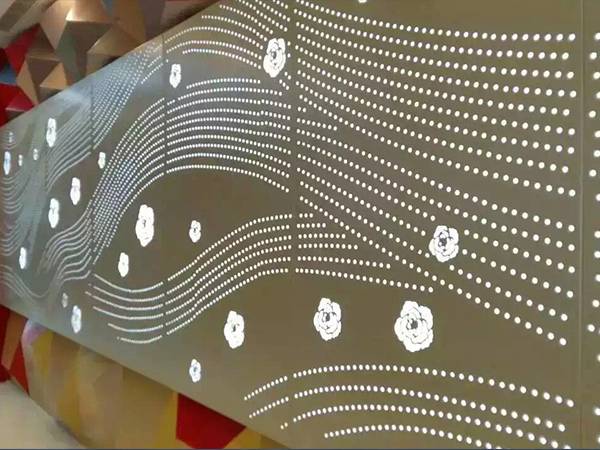

Perforated aluminum veneer

Skeleton aluminum veneer

Great wall aluminum veneer (corrugated aluminum veneer)

-

According to the surface decorative effect of aluminum veneer can be divided into:

PVDF coated

Anodized

Decorating with film

Brushed

Mirror PVDF coated aluminum veneer

Anodized aluminum veneer

Film decorative aluminum veneer

Brushed aluminum veneer

Mirror aluminum veneer

-

According to the different parts of the aluminum veneer used can be divided into:

External curtain wall

Interior decoration

Ceiling External cladding aluminum screen

Interior aluminum veneer

Ceiling aluminum veneer

3003 aluminum alloy is one of the most widely distributed types of aluminum on the market today and for good reason. It has a good finish, excellent formability, welds well, has moderate strength, and resists corrosion.

5052 aluminum alloy has some of the best welding characteristics, great finishing qualities, and excellent saltwater corrosion resistance performance, but is not easily machined. This alloy is also not heat-treatable and can only be strengthened using the work-hardening process, with 5052-H32 being the most common procedure.

6061 aluminum is famous for its high strength, good weldability and machinability, and good corrosion resistance performance. It is particularly useful in structural materials, as the strength of 6061 aluminum helps keep tall buildings from falling over.

The main reason to choose 6061 aluminum over 3003 aluminum is its superior strength. This is shown by comparing their yield strengths, which is the minimum amount of stress that will cause these materials to permanently deform.

Generally, 6061 aluminum is best used for machining, while 5052 is used for sheet metal and welding applications.

| Material Properties | Type 6061 Aluminum Alloy | Type 3003 Aluminum Alloy | ||

|---|---|---|---|---|

| Units | Metric | English | Metric | English |

| Yield Strength | 276 MPa | 40000 psi | 185 MPa | 26800 psi |

| Bearing Yield Strength | 386 MPa | 56000 psi | 262 MPa | 38000 psi |

| Shear Strength | 207 MPa | 30000 psi | 110 MPa | 16000 psi |

| Hardness (Brinell) | 95 | - | 55 | - |

| Machinability | Good | - | Fair | - |

| Material Properties | Type 6061 Aluminum | Type 5052 Aluminum | ||

|---|---|---|---|---|

| Units | Metric | English | Metric | English |

| Yield Strength | 276 MPa | 40000 psi | 193 MPa | 28000 psi |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | 70.3 GPa | 10200 ksi |

| Fatigue Strength | 96.5 MPa | 14000 psi | 117 MPa | 17000 psi |

| Thermal Conductivity | 167 W/m.K | 1160 Btu-in/hr-ft2-°F | 138 W/m.K | 960 Btu-in/hr-ft2-°F |

| Machinability | Good | Poor | - | - |

Inquiry for Our Product

Anping Zhuote Metal Products Co., Ltd.

E-mail:

info@perforatedsheet.ltd

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.