Perforated Sheets – Easy to Handle, Operate & Speed-Controlled

CNC perforated sheet is a kind of perforated metal sheet manufactured by a computerized CNC punching process. This process can achieve high precision, high speed, and high efficiency production, which has more advantages than traditional manual punching. As a manufacturer, we can use CNC punching to process various materials such as architectural decorative panels, stainless steel, galvanized steel, aluminum, copper, and brass. Simple shapes such as squares, circles, or hexagons can be formed directly in the sheet, while complex shapes can be realized by arranging many square or circular cutouts around the perimeter. With our powerful Radan sheet metal software, we can provide our clients with high quality, customized services to meet their diverse needs.

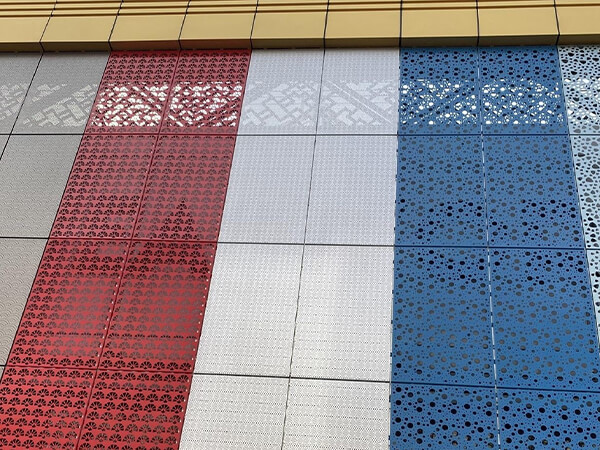

Shaped metal perforated sheet

Colorful shaped metal perforated sheets

Shaped metal perforated sheets in 2 colors

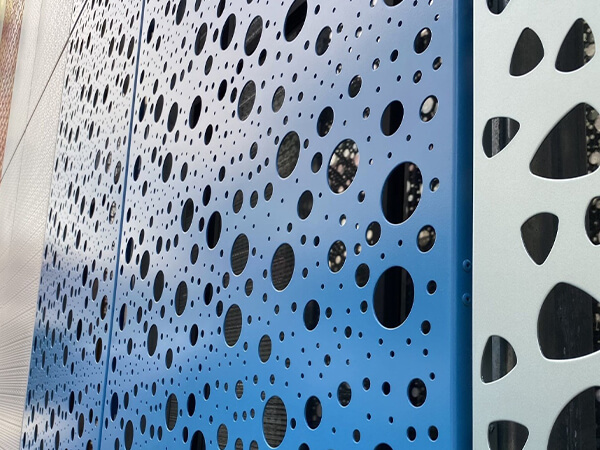

Perforation aluminum solid sheet

CNC engraved metal facade aluminium sheet

Perforated metal screen aluminum panels

All aluminum sheets are prefabricated according to the client's design and drawings. You just need to make a frame prepare some bolts for installation, and finally finish the gaps between the panels with some sealant. Building enclosures and decorations is an easy job.

Metal cladding panels are made of high quality, high strength aluminum alloy sheets with common thicknesses of 1.5 mm, 2.0 mm, 2.5 mm, and 3.0 mm. The maximum width of the panels is up to 2,000 mm and the maximum length is up to 6,000 mm for the 3003-H14 or 1100-H14 aluminum alloy series. It consists of panels, reinforcement bars, and braces. The corner bracket can be stamped and formed directly from the panel, bent to shape, or the corner bracket can be riveted to the small folded edge of the panel. The steel reinforcement is connected with the welded screws at the back of the panel to make it a solid whole, which greatly improves the strength and stiffness of the solid aluminum cladding panel, and ensures the flatness and resistance to wind pressure and vibration of the aluminum cladding panel in long-term use. If sound insulation is required, high-efficiency sound insulation materials can be installed inside the aluminum cladding panels.

Inquiry for Our Product

Anping Zhuote Metal Products Co., Ltd.

E-mail:

info@perforatedsheet.ltd

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.